Inflatable seals

To solve the sealing problem of two elements coming into intermittent contact, the safest, most effective and simple solution is the inflatable gasket.

Infla-Sealing inflatable gaskets are custom-designed to meet customer requirements.

They are gaskets that can work in a wide temperature range from - 60 °C to + 220 °C pressure and vacuum. They can be applied in all industrial, food and pharmaceutical sectors.

Thanks to many years of experience in the field of inflatable gaskets, Infal-Sealing has developed a technology and know-how for the production and marketing of its product. This is mainly due to the control and testing systems adopted for individual applications, which allow it to give feedback with specific tests on whether the gasket will last in the specific application.

Gaskets can be manufactured using various elastomer rubbers or from silicone compounds that can also be used in the pharmaceutical industry with FDA and USP Pharma Class VI certifications

Applications

Doors/hatches, wind tunnels, jet engine test cells, cockpit canopies

Suction rollers for pulp / paper, doctor blader, cutters, markers

Processing of semiconductors, filters, actuators, washers, robotics, optics

Door seals for high-speed trains, freight containers marine portholes, lifting platforms, loading hatches, maintenance drive shafts

Locks, door seals for pressure chambers

Door seals, doctor blades, continuous casting, oven seals

Medical sterilizers, clean rooms, optics, robotics

Processing equipment, mixers, hoppers, mixers, chutes, valves

Door seals, mixers, robotics, conveyor brakes, dryers, autoclaves

Mixers, robotics, autoclaves, ovens, clean rooms

Aerospace:

Paper mills:

Telecomunications:

Transportation:

Textile Industry:

Primary metal:

Medical:

Lav. Chemistry:

Food:

Pharmaceutical:

Nuclear:

Access doors, cofferdams, tank doors, nozzle dams

Operation

The inflatable Infla-Sealing gaskets, thanks to the adherence to the seat where they are inserted, swell and deflate thanks to elastomer elasticity used. It is advisable not to inflate gaskets if not completely installed in their operating site, in order to prevent them from bursting in an uncontrolled environment.

Once assembled and inserted in their seat, seals must be brought to the design pressure to obtain the desired seal (the gasket must be inflated between 1.3 and 1.5 bars, in order to counteract internal pressure

Construction

The elements that characterize the quality of the Inflatable seals are:

a) the quality of the raw material for the extrusion of the desired profile

b) the joint of the sections of the profile

c) the joint of the valve

The correct execution of the test joint on the head of the inflatable gasket, such as that of the valve, are the key to the best durability of the gasket, bringing the element to be in continuity with the extruded profile itself.

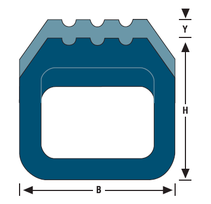

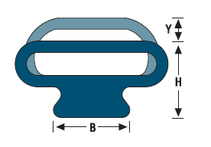

Standard high pressure profile

| Code | A x B | B | H | Y |

IS201001 | 14,0 x 10,0 | 14 | 11 | 3 |

IS201002 | 14,0 x 10,0 | 14 | 11 | 3 |

IS201003 | 14,0 x 14,0 | 14 | 15 | 2 |

IS201004 | 16,0 x 14,0 | 16 | 15 | 3 |

IS201005 | 24,0 x 22,5 | 24 | 23 | 4 |

IS201006 | 27,0 x 16,0 | 27 | 17 | 3 |

IS201007 | 27,0 x 18,0 | 27 | 19 | 4 |

IS201008 | 28,0 x 18,0 | 28 | 19 | 3 |

IS201009 | 31,5 x 16,5 | 32 | 17 | 4 |

IS201010 | 34,0 x 21,0 | 34 | 22 | 3 |

IS201011 | 34,0 x 26,5 | 34 | 27 | 5 |

IS201012 | 35,0 x 23,0 | 35 | 24 | 3 |

IS201013 | 36,0 x 32,0 | 36 | 33 | 3 |

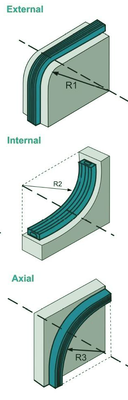

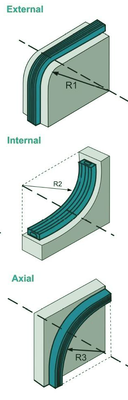

| Profile | Dim. | External R1 | Internal R2 | Axial R3 |

IS201014 | 16,0 x 14,0 | 50 | 78 | 48 |

IS201015 | 27,0 x 16,0 | 70 | 83.5 | 111 |

IS201016 | 34,0 x 21,0 | 70 | 87.5 | 106 |

IS201017 | 36,0 x 32,0 | 80 | 87.5 | 122 |

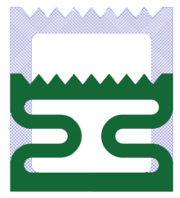

Standard low pressure profiles

| Code | A x B | B | H | Y |

IS202001 | 23,0 x 13,5 | 23 | 14 | 5 |

IS202002 | 30,0 x 19,5 | 30 | 20 | 5 |

IS202003 | 30,0 x 20,0 | 30 | 20 | 5 |

IS202004 | 40,0 x 27,0 | 40 | 27 | 13 |

IS202005 | 60,0 x 33,0 | 60 | 33 | 12 |

IS202006 | 60,0 x 35,0 | 60 | 35 | 15 |

We will then show you other possibilities of usable profiles with different characteristics for each application

Assembly

This profile, called OMEGA, is normally installed with a strap that blocks it to the surface of the machine or from an element that allows it to remain adherent to the lower surface.

By applying a pressure of 1.5 bar, a maximum extension of the H + Y seal is obtained

| Profile | Dim. | External R1 | Internal R2 | Axial R3 |

IS202002 | 30,0 x 19,5 | 60 | 100 | 90 |

IS202003 | 30,0 x 20,0 | 60 | 100 | 90 |

IS202004 | 40,0 x 27,0 | 90 | 117 | 160 |

IS202005 | 60,0 x 33,0 | 100 | 165 | 230 |

IS202006 | 60,0 x 35,0 | 100 | 165 | 230 |

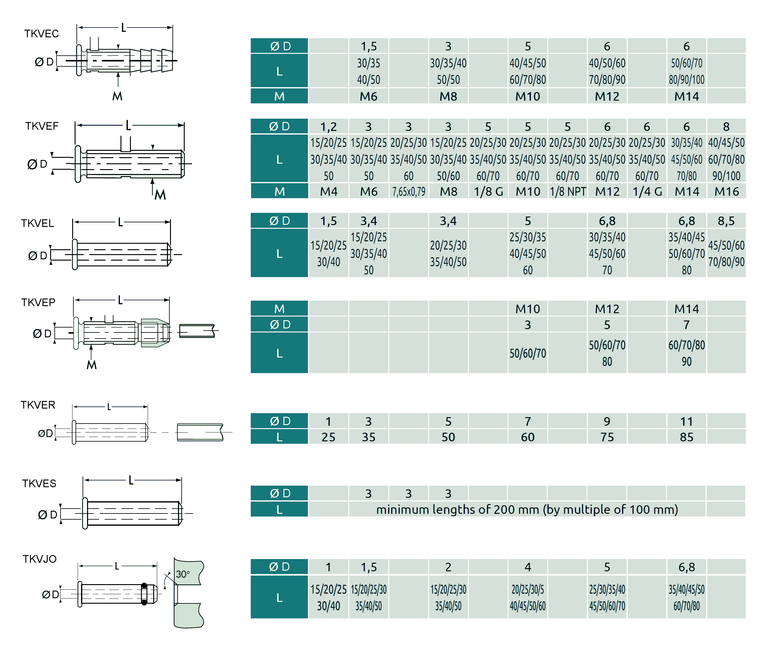

Fittings and valves

Our standard fittings and valves are made of AISI 316 Stainless Steel. We also produce fittings in any other material, such as bronze, brass and elastomers.

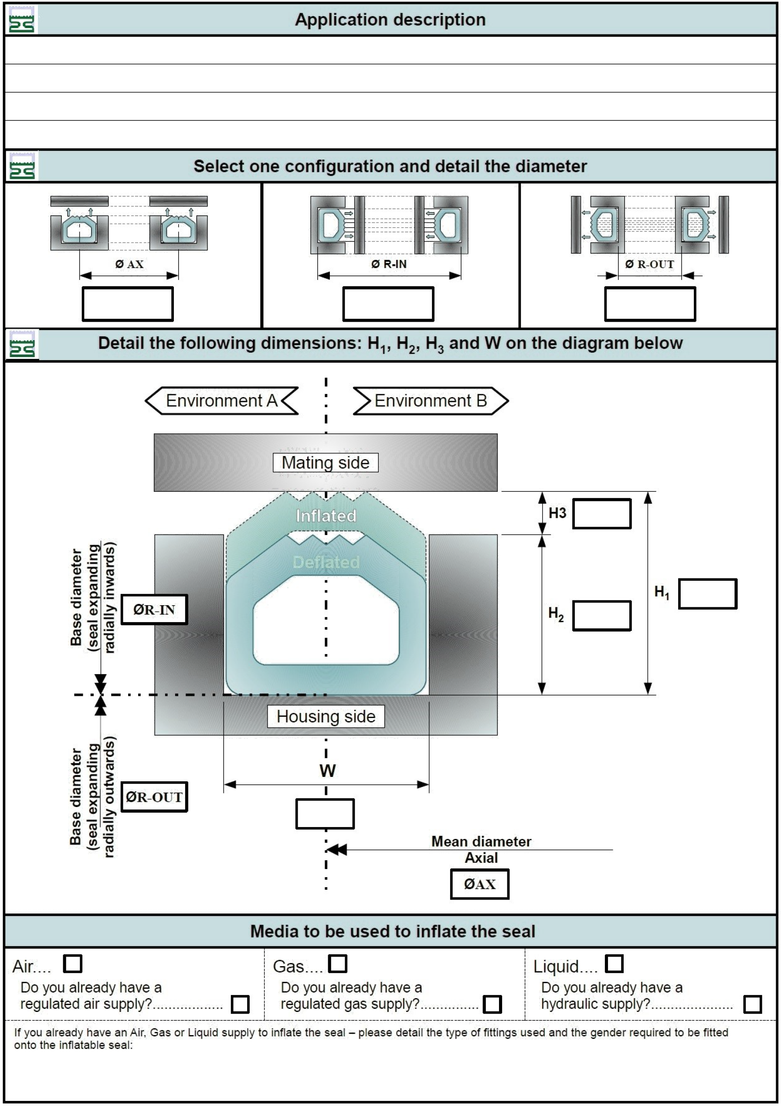

Technical Information for New Applications